2-DTech: harnessing graphene nanotechnology

Carbon composites sit at the forefront of automotive lightweighting. Once the preserve of motorsport and high-end supercars, these materials are now being embraced by the mainstream – particularly in electric vehicles (EVs) where weight reduction can play a key role in increasing range.

Even with their compelling advantages, the cost-to-benefit ratio of traditional carbon composites remains a concern in mainstream applications, while less cost-sensitive markets continue to push for new technologies that could enhance the material properties even further.

Versarien plc acquired 2-DTech Limited, a spin-out from the University of Manchester, in 2014 and has since developed novel and innovative techniques of reinforcing carbon fibre with graphene nano platelets (GNPs).

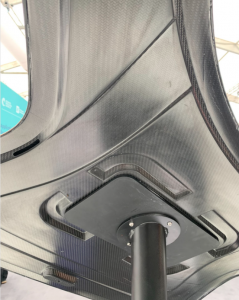

The nano particles are added to epoxy resin, which is then combined with carbon fibres as the basis of a of pre-preg (‘pre-impregnated’) with resins and then cured) woven material. 2-DTech’s initial investigations had shown that adding just a small amount of graphene to the material (less than 1% by weight) could increase the mechanical strength by around 10%.

This increased strength means that less material is typically required for a given part, reducing the weight and cost. What’s more, the material is compatible with low-cost production techniques that don’t require an energy intensive autoclave (which would need high heat and pressure in the vessel). In total, its cost is projected to be around 10% lower than traditional carbon fibre.

Grant funding

2-DTech approached the Advanced Propulsion Centre (APC) for help with commercialising the technology. The firm joined the APC’s Technology Developer Accelerator Programme (TDAP) in April 2020, and in the final part of the programme they worked on a project that also involved Lotus Cars, SHD Composites Ltd and the Advanced Manufacturing Resource Centre (AMRC). In total, 2-DTech was awarded £104,500 of grant funding from the APC.

2-DTech’s aim was to demonstrate the graphene-enhanced material with a prototype body panel for the Lotus Evija electric hypercar. Previously, the material had only been produced in simple shapes such as flat sheets, so a working prototype represented a significant step up in technology readiness.

Targets were set to improve mechanical strength by at least 10% and reduce the price by 10% (with a stretch target of 25%) compared to the existing carbon fibre part. The prototype part would also need to meet Lotus’ standard production specifications for paint and surface quality.

“One of the best things about TDAP for us was the opportunity to work with the partners in the project,” comments Jim Barnett, Head of Programme Management at Versarien. “It’s given us the legitimacy of working with an internationally recognised brand, as well as very valuable technical partners.”

Business case

Other major benefits included help to identify key markets, along with a system of gateways and reviews that has pushed the company to continuously develop its business case.

“The project has helped us commercialise the materials,” comments Barnett. “As engineers, we were very much focused on the technical side, but the APC helped us to link that with the commercial partners in the automotive sector.”

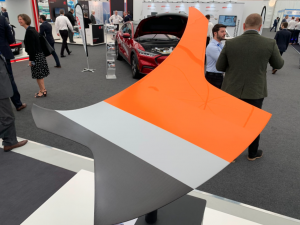

2-DTech achieved all of the goals that it set at the beginning of the project, and the prototype part was successfully displayed next to its host vehicle, the Evija. That was exhibited on Lotus’ stand at the Cenex LCV show in 2021. As part of wider successes, the company now has the facilities required to process larger volumes of material. It has also entered discussions with several automotive OEMs, covering a range of different markets, to investigate full-scale production.

- 2-DTech prototype on display at Cenex LCV 2021