Automotive power electronics value chain

The power electronics (PE) value chain provides a framework for growing the UK’s semiconductor manufacturing industry, whilst highlighting dependencies through the supply chain.

Developed by the Advanced Propulsion Centre (APC), with experts and stakeholders from industry, academia and funding and support bodies, the updated power electronics value chain shows an end-to-end supply chain view of materials and components required for volume manufacturing of automotive inverters, converters, and onboard chargers.

Why is the power electronics value chain useful?

This is the first document of its kind to demonstrate the complete value chain; identifying what’s needed to build a robust end-to-end UK supply chain. It will be a valuable tool to support industry, academia, government, and the investment community navigate what’s required and highlight where the gaps are. As the UK moves to secure its electric vehicle (EV) manufacturing industry, the PE value chain will play a vital role in identifying where action is needed to anchor the value-add in the UK and informs upskilling and training requirements.

Understanding the value of power electronics in electric vehicles

Power electronics are fundamental to electric vehicles. At the heart of these devices are semiconductors, commonly referred to as chips. Semiconductors are needed for a wide range of applications on a vehicle, ranging from the entertainment system to power-steering. Crucially, they are an integral part of any electrified powertrain, supplying and controlling the current and voltage throughout the drive system. Electric vehicles use 30% more chips than ICE (internal combustion engine) vehicles meaning shortages will impact on 2030 manufacturing targets.

There are three main power electronic components on board battery electric vehicles; an inverter, a DC-DC converter, and an onboard charger (OBC).

- An inverter converts DC power from the vehicle’s battery to AC power to drive the electric motor. These high-power devices (30-400 kW) are either standalone or integrated with the electric motor into an electric drive unit (EDU).

- A DC-DC converter on a BEV or PHEV decreases (steps-down) voltage from the high voltage battery, e.g., 400-800 V, to low voltages as needed by the vehicle’s auxiliary systems. These are typically low power devices (3-7 kW), but high power on a FCEV.

- An onboard charger (OBC) takes AC power from the electrical grid and converts it to DC for storage on the vehicle’s battery. These are typically rated at 3-23 kW.

Key semi-conductor terminology

- Wafer – A wafer (also called a slice or substrate) is a thin slice of semiconductor, used for the fabrication of integrated circuits and, in photovoltaics, to manufacture solar cells.

- Epi-wafer – An epitaxial wafer (commonly called epi-wafer) is a wafer of semiconducting material made by epitaxial growth (epitaxy) for use in photonics, microelectronics, spintronics, or photovoltaics. Layers can be of different materials, suited to its intended function.

- Die – An electronic die is a small block of semiconducting material upon which integrated circuit parts and functions are fabricated.

- MOSFET – A metal-oxide semiconductor field-effect transistor is a device which can amplify and switch electronic signals.

- Power module – A power module is an assembly containing several power components, mostly power semiconductor devices, internally interconnected to perform a power conversion function.

Insights

Silicon carbide (SiC) semiconductors are growing in popularity

SiC MOSFETs offer huge potential for power electronic systems due to their reduced conduction and switching losses and ability to withstand higher junction temperatures.

By operating at higher switching frequencies and voltages of 800V +, SiC provides a compounding effect from improved power conversion efficiencies of 5-15% and significant weight savings to the electric motor, cabling and the cooling system.

Although SiC inverters cost more to produce than Si inverters, efficiency gains across the complete powertrain system can reduce the battery size by 3-5% (for a given range), offering a valuable route to offsetting costs and reducing critical battery material demand.

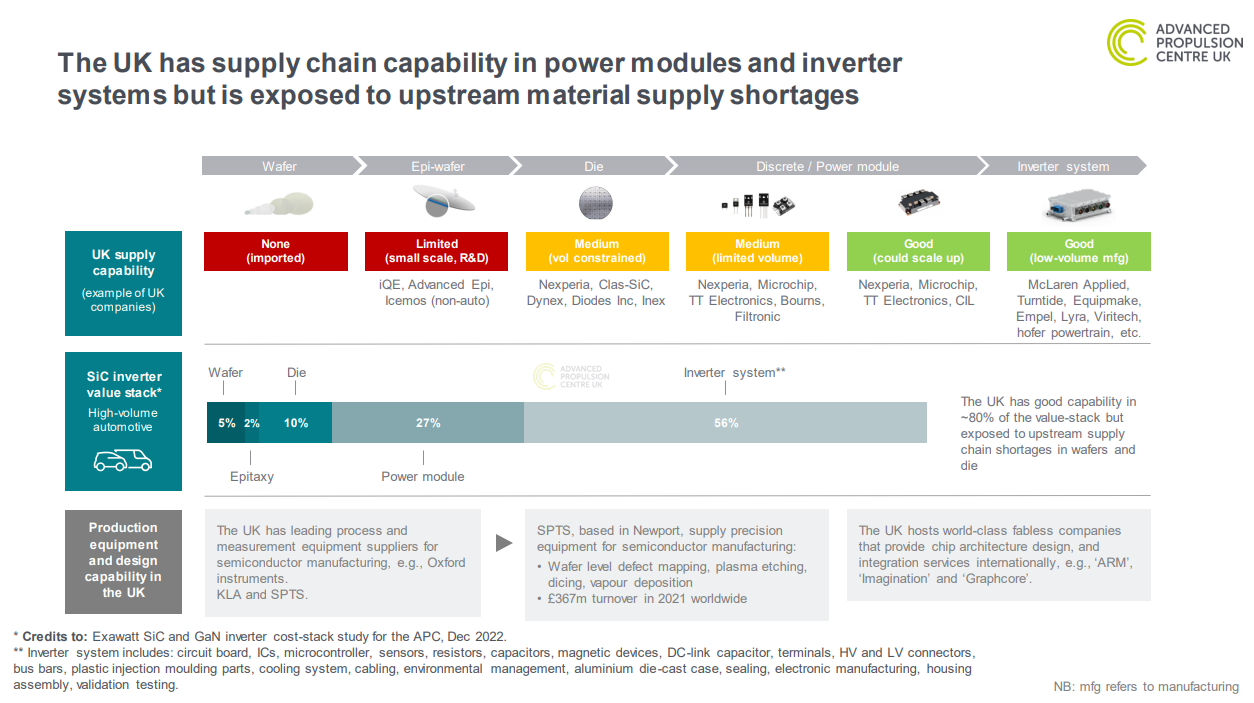

We have identified that with a focus on SiC and gallium nitride (GaN) semiconductors, then the UK has a credible chance of creating an end-to-end supply chain. Silicon carbide is the preferred front runner for future electric vehicle power distribution, control, and supply management. It is cost-effective when its benefits are applied across the powertrain system, providing power efficiency gains, and reducing the size of motors and the battery pack.

Semiconductor shortages

There have been significant product delays, factory closures and supply chain issues that the automotive sector has faced from chip shortages in recent years.

Internationally

As of mid-2022, the lead times for most semiconductors, no matter the type, were running at 40 to 50 weeks, with many in the 50 to 60-week range. Efforts to secure supplies and furthermore build in-house production capabilities are seeing large investments internationally and vertical integration of supply chains.

In July 2022, the United States Senate and House of Representatives passed the CHIPS and Science Act, providing $52 billion in government subsidies for research and production of semiconductors in the U.S.

The European Commission proposed the European Chips Act in February 2022, aiming to double the European share of global microchip production by 2030 and reduce supply dependencies.

In the UK

Building a resilient semiconductor supply chain to serve the UK’s automotive sector is essential.

Discover more about power electronics in our roadmaps: towards 2040

The Automotive Council roadmaps towards 2040, published by the APC, outline the key trends in propulsion technologies and how future vehicles might evolve to meet mobility demands and today’s environmental challenges.

This special episode of the Road to Net Zero podcast takes a deep-dive into the complex subject of power electronics.

- Hear from Technology Trends Consultant, Bhavik Shah, as he provides a short explainer of our recently released Power Electronics Value Chain and insight report.

- Listen to a live panel discussion, hosted by journalist David James, featuring McLaren Applied, Clas-sic Wafer Fab Ltd and Exawatt.

- Hear from APC CEO, Ian Constance, as he summarises what power electronics are and why they are important for the UK’s automotive sector.

Published: 20/02/2023

Automotive power electronics value chain

Developed alongside experts and stakeholders from industry, academia and funding and support bodies, this first-of-its-kind power electronics value chain shows an end-to-end supply chain view.

Published: 20/02/2023

Automotive power electronics value chain

Developed alongside experts and stakeholders from industry, academia and funding and support bodies, this first-of-its-kind power electronics value chain shows an end-to-end supply chain view.