Technology Developer Accelerator Programme (TDAP)

Enable Manufacturing

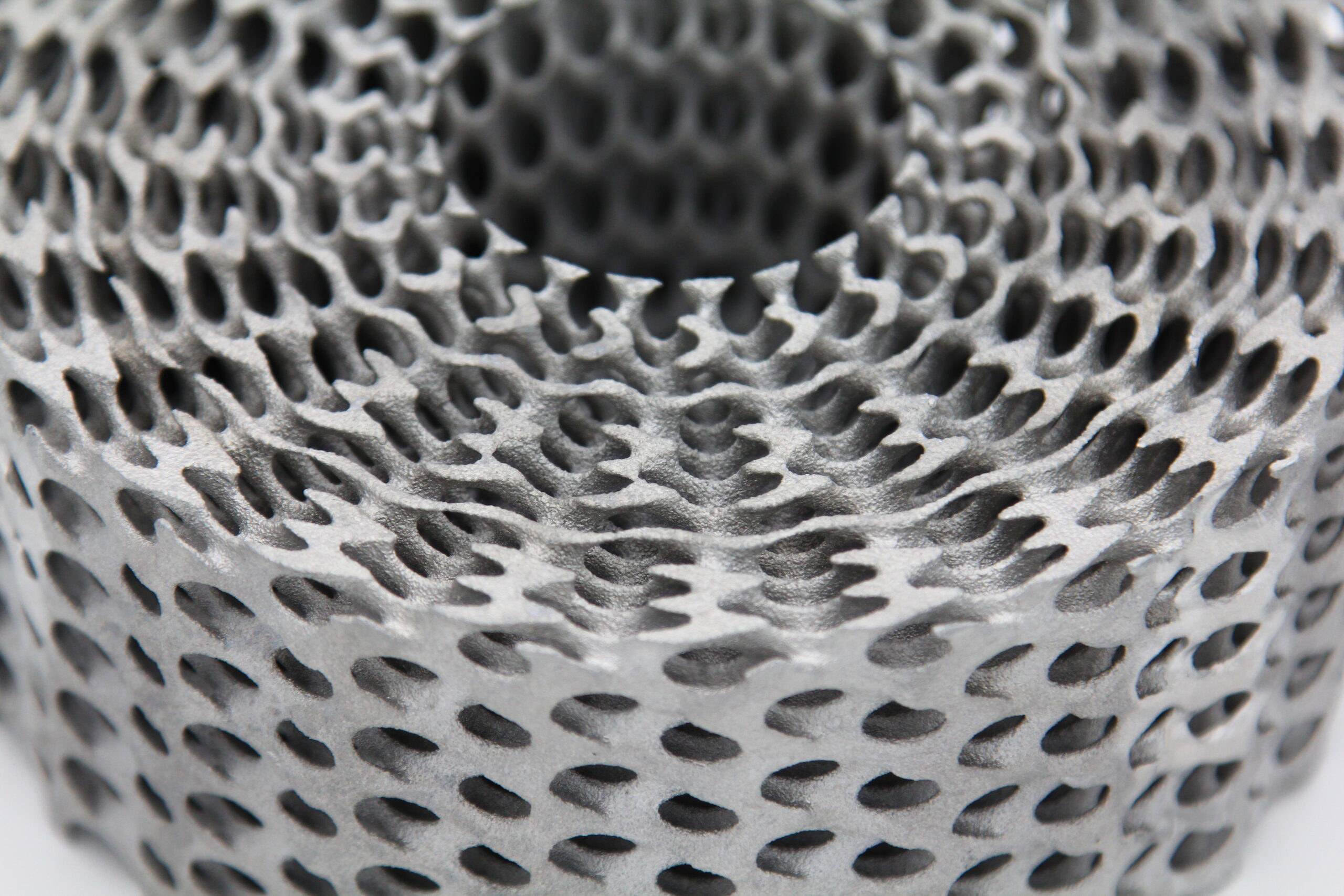

Additive Casting®, for automotive components

Enable Manufacturing’s Additive Casting® process combines the best of 3D printing and traditional casting, to manufacture complex metal parts, of any size, cost–effectively.

Project Highlights

- Additive Casting® produces highly-complex cast metal parts, without using any tooling, in over 130 different metals at 80% lower cost than other 3D printing technologies.

- Enable Manufacturing’s approach eliminates the need for tooling, allowing for more complex parts to be manufactured, from first prototype to a large annual production volume.

- The technology bridges the gap between traditional casting and state-of-the-art manufacturing, offering the volume benefits of casting while increasing possible complexity, cutting lead times and eliminating the need for expensive tooling.

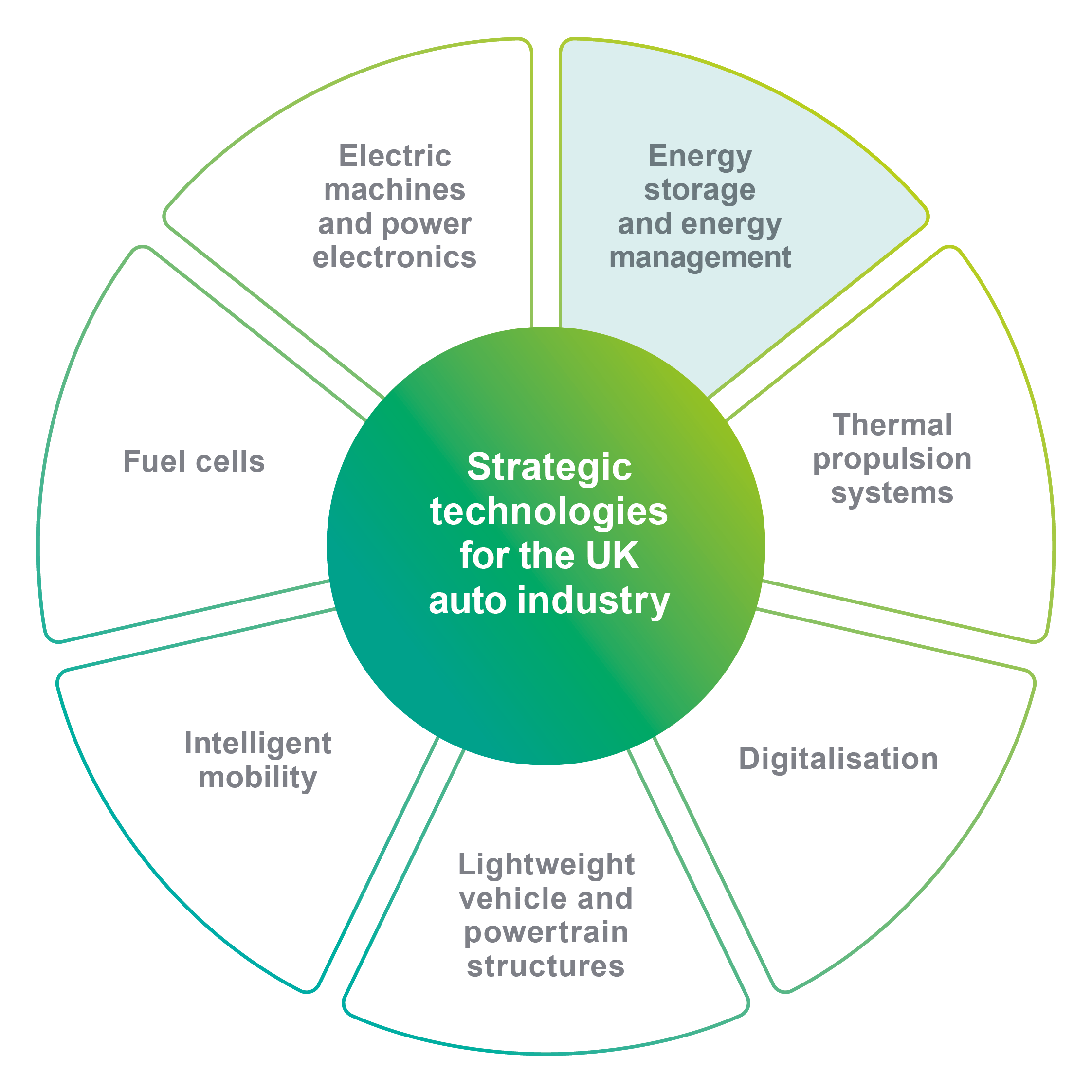

- Our Technology Developer Accelerator Programme (TDAP) helped to develop and refine strategy and business plans and engage with automotive customers. From this customer engagement, Enable Manufacturing was able to develop and manufacture two demonstrator parts, with one leading to a new patent and the eventual serial production of an electric motor endplate for Continental.