£54 million investment as UK automotive industry accelerates towards net-zero emissions

- The Advanced Propulsion Centre (APC) welcomes £54 million commitment across three innovative automotive projects in the latest round of R&D funding

- Investment in hydrogen fuel cells for buses, lightweight electric vehicle powertrains for heavy goods vehicles and motorsport technology built into high efficiency motors for cars and vans

- Transformational programmes across England, Northern Ireland, Scotland and Wales forecast to create and safeguard nearly 10,000 jobs

More than £54 million in combined government and industry funding has been committed to three innovative projects for cars, buses, heavy goods vehicles and vans across the UK, co-ordinated by the Advanced Propulsion Centre (APC).

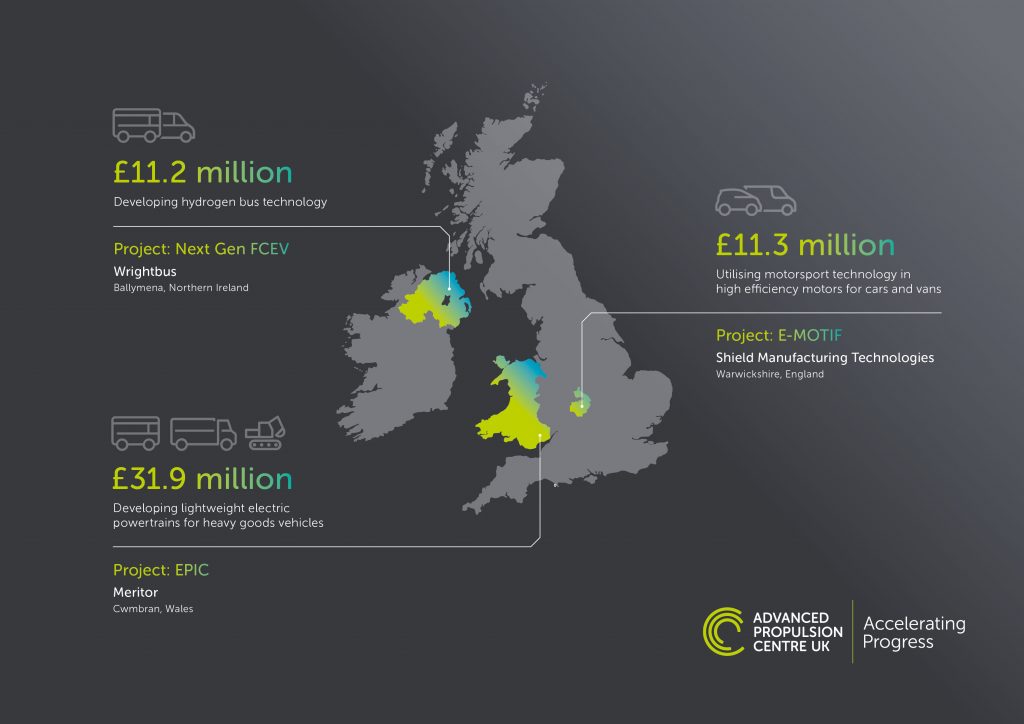

- In Northern Ireland, £11.2 million for the development and manufacture of low-cost hydrogen fuel cell bus technology and a hydrogen centre of excellence with Wrightbus in Ballymena, to further the development of hydrogen technology and drive product sales across the world.

- In Wales, lightweight electric powertrains for heavy goods vehicles will be developed in Cwmbran led by Meritor in a £31.9 million programme which will also see a new technology centre built in Scotland.

- In Warwickshire, £11.3 million has been committed through Shield Manufacturing Technologies to develop and manufacture an energy recovery system developed in motorsport and integrated with an e-axle and motor, to reduce energy use in cars and vans in a transformational project for the UK’s production of motors and inverters.

Ian Constance, Chief Executive at the APC said:

We are delighted to have guided the latest investment of more than £54 million in the development and production of innovative powertrains to further accelerate the transition of the automotive sector to a net-zero future. The funding will enable the UK to apply its world-class innovation and experience in electrification of vehicles across the supply chain in Great Britain and Northern Ireland. From fuel cell technology for buses, designed and built in Ballymena, a lightweight electric powertrain for commercial vehicles developed and manufactured in Wales and an integrated motor and energy recovery systems system for cars and vans based on motorsport technology in Warwickshire, today’s announcement secures and creates nearly 10,000 jobs and will cut CO2 emissions equivalent to removing the lifetime emissions of nearly 1.8 million cars.

Business Secretary Kwasi Kwarteng said:

The UK is leading the world by developing cutting edge technology that will help to tackle climate change and lead to a green, competitive future for our automotive supply chain. These projects will not only help accelerate the wider application of greener technology in lorries and buses, but will also help generate the high-skilled jobs to level up communities across the UK while ensuring we build back greener from the pandemic.

This funding announcement builds on the recent launch of the Government’s national Bus Back Better strategy and the Prime Minister’s 10 Point Plan for a Green Industrial Revolution, both of which aim to accelerate the shift to zero emission vehicles and decarbonise the UK’s transport networks.

Transport Minister Rachel Maclean said:

As we look to reduce our carbon emissions, strive towards our net-zero goals and level up right across the UK, the whole transport sector will need to embrace new innovative technology such as green hydrogen and these projects are a fantastic example of doing just that. I’m proud to see the UK leading the way in the global transition to zero-emission vehicles. In the next decade, we’ll continue to be at the forefront of their design, manufacture and use as we build back greener.

Projects to receive funding from the latest Advanced Propulsion Centre funding competition APC17 include:

The UK is a global leader in bus design and manufacturing. Wrightbus in Ballymena is developing hydrogen-powered fuel cell electric vehicle single and double-deck buses. This programme will enable higher volume production at lower cost and create a centre of excellence for zero emissions hydrogen technology to upskill and share knowledge in the UK.

Jo Bamford, Wrightbus Executive Chairman, said:

The funding will allow us to realise our ambitions of creating a centre of excellence for zero emission technology in Ballymena, enabling us to produce the next generation of world-leading hydrogen buses at a higher volume and a lower cost than ever before. It will safeguard more than 1,000 skilled jobs and will allow us to create more than 3,000 additional jobs over the next 10 years, giving a significant boost to the wider economy in Northern Ireland.

Secretary of State for Northern Ireland, Brandon Lewis said:

Northern Ireland and the local economy thrives on innovation, manufacturing and technological advancements, leading the charge in allowing us to reach our ambitious goal of a net zero future by 2050. With a landmark investment of £11.2 million this will enable Wrightbus to become a centre of excellence for zero-emission technology in the heart of Ballymena. This is outstanding news for the people of Northern Ireland, protecting more than 1,000 skilled jobs and creating more than 3,000 additional jobs over the next 10 years. This will continue to level up our local economy, allowing Wrightbus to continue producing the next generation of world-leading hydrogen buses.

EPIC (Electric Powertrain Integration for Heavy Commercial Vehicles)

The next generation of zero emissions heavy commercial vehicles need lightweight ‘smart’ powertrains to manage extreme levels of electrical power. The EPIC project led by Meritor in Cwmbran integrates the key elements of motor, inverter, gearbox, differential and brakes in a single lightweight system for vehicles up to 44 tonnes and includes coaches, off-highway and construction vehicles.

John Bennett, Vice President and Chief Technology Officer at Meritor said:

With this award, our consortium will develop a game-changing electric powertrain for heavy-duty 4×2 and 6×2 vehicles up to 44 tonnes. This technology will provide commercial vehicle OEMs with the optimal solution to meet EU 2025 CO2 reduction targets, in addition to a host of other product benefits including greater efficiency, reduced weight, longer-range capability, and far greater application flexibility when compared to existing systems.

Ken Hogan, Vice President, Truck, Europe, China, Japan and ASEAN Meritor said:

This grant will put Meritor’s highly-skilled Welsh-based engineering team at the forefront of advanced commercial vehicle technologies, positioning South East Wales as the premier location for companies developing clean transportation and technologies. Meritor’s existing air disc brake facility in Cwmbran will house a new European eMobility Centre of Excellence with expanded laboratory and R&D facilities.

Secretary of State for Wales, Simon Hart said:

As we work towards net zero by 2050, South Wales will be a hub of innovation and green technology as we transform the UK economy over the coming years. The investment in electric propulsion systems in Cwmbran will create more than 1,000 skilled jobs. It follows recent UK Government backing for the Global Centre of Rail Excellence and to develop a net zero industrial zone across South Wales as we ensure that the region’s proud heritage is continued with the industries of the future.

e-MOTIF (e-axle with MOTor Inverter and Flywheel)

Weight saving and reducing energy consumption are key to winning in motor racing. The e-MOTIF project led by Shield Manufacturing Technologies in Warwickshire combines lightweight energy recovery technology from motorsport with a new motor and inverter for cars and vans to cut energy consumption and CO2 The e-MOTIF project is scalable and cost effective for global manufacturers and will lead to three new manufacturing centres opening across the UK.

Chris Shield, Managing Director of the Shield Group said:

Shield Manufacturing Technologies is delighted to be working with APC and our partners to accelerate the development and production readiness of cutting-edge engineered technologies. The evolving market opportunity for this family of power-dense electric drive modules will generate significant numbers of skilled roles with associated investment across Shield’s facilities in the Midlands and opportunities for the region’s supplier base.